Carbon Capture Utilization and Storage

What

is CCUS?

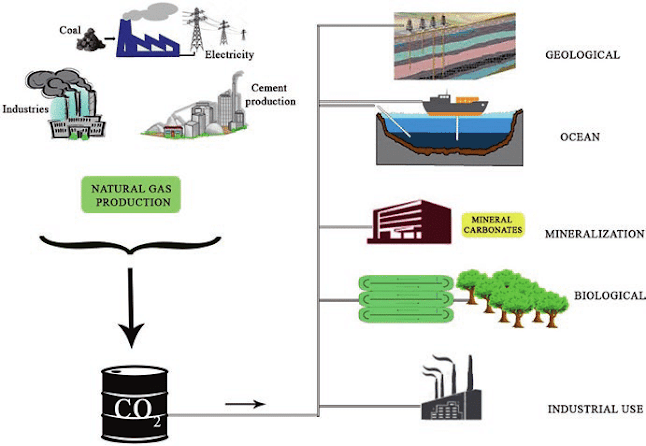

Carbon

capture, utilisation and storage (CCUS) refers to a suite of technologies that

can play an important and diverse role in meeting global energy and climate

goals. CCUS involves the capture of CO2 from large point sources, including

power generation or industrial facilities that use either fossil fuels or

biomass for fuel.

The

CO2 can also be captured directly from the atmosphere. If not being used

on-site, the captured CO2 is compressed and transported by pipeline, ship, rail

or truck to be used in a range of applications, or injected into deep

geological formations (including depleted oil and gas reservoirs or saline

formations) which trap the CO2 for permanent storage.

Why

CCUS?

The

reason CCUS will have to play a key role is simple: Despite rapid recent growth

in renewable sources like wind and solar, the world still relies on fossil

fuels to meet about 80 percent of its energy needs. Shifting the balance in the

world’s energy mix from a reliance on fossil fuels to renewable energy sources will

require considerable time.

Much

of the focus today is on decarbonizing electric power production, but it should

be noted that only about one quarter of global greenhouse gas (GHG) emissions

are from electricity. Coal, the most carbon-intensive fuel, accounts for about

40 percent of power generation globally. Even if coal consumption were to

plateau within the next few years, it will remain the fuel of choice in Asia

for decades to come. Coal is a cheap, reliable, and secure energy source in

China and India, two countries with the fastest growth in electricity demand.

Rapid closure of coal-fired power plants in these countries is economically and

politically infeasible.

There

are comparable obstacles to changing the energy mix in other sectors. Shifting the

world’s car, truck, plane, and shipping fleets from oil-based to low carbon

fuels will require decades, not years. And in industries like refining,

petrochemicals, and cement and steel production, which together generate about

20 percent of global GHG emissions, carbon abatement is even more challenging.

Four Main Parts to a CCUS

System

1. The

CO2 gas is captured before or after fossil fuels are burned and compressed into

a liquid form.

2. The

liquid CO2 is transported via pipeline to a utilization or geologic storage

site.

3. At the

utilization site, CO2 is transformed into usable materials. Sometimes the

utilization site is also the storage site.

4. At the

storage site, the CO2 is injected deep into the subsurface of the Earth where

it is safely stored and monitored.

All parts of the CCUS

system—CO2 capture, transport, utilization, and storage—are currently done on a

small scale. If CCUS can be used on a large scale, there is potential for CCUS

to capture and store up to 90 percent of the CO2 emitted into the atmosphere

from stationary fossil fuel plants.

How can CO2 be used?

CO2 can be used as an input to a range of products

and services. The potential applications for CO2 use include

direct use, where the CO2 is not

chemically altered (non-conversion), and the transformation of CO2 to a useful product through chemical and

biological processes (conversion).

Today around 230 Mt of CO2 are

used globally each year, primarily to produce fertilisers (around 125 Mt/year)

and for enhanced oil recovery (around 70-80 Mt/year). Other commercial uses of

CO2 include food and beverage production, cooling, water

treatment and greenhouses. New CO2 use pathways include: fuels (using

carbon in CO2 to convert hydrogen into a synthetic hydrocarbon

fuel); chemicals (using carbon in CO2 as an

alternative to fossil fuels in the production of some chemicals); and building

materials (using CO2 in the production of building

materials to replace water in concrete or as a raw material in its

constituents.)

How is CO2 stored – and is it

safe?

Studies have shown that CO2

can be safely stored underground, such as in deep, porous rock formations,

for thousands of years, and we've even found natural pockets of CO2 that

have existed for millions.

There are several types of

reservoir suitable for CO2 storage, with deep saline formations

and depleted oil and gas reservoirs having the largest capacity. Deep saline

formations are layers of porous and permeable rocks saturated with salty water

(brine), which are widespread in both onshore and offshore sedimentary basins.

Depleted oil and gas reservoirs are porous rock formations that have trapped

crude oil or gas for millions of years before being extracted and which can similarly

trap injected CO2.

When CO2 is

injected into a reservoir, it flows through it, filling the pore space. The gas

is usually compressed first to increase its density and the reservoir typically

must be at depths greater than 800 metres to retain the CO2 in

a dense liquid-like state. The CO2 is permanently trapped in

the reservoir through several mechanisms: structural trapping by the seal,

solubility trapping where the CO2 dissolves in the brine

water, residual trapping where the CO2 remains trapped in pore

spaces between rocks, and mineral trapping where the CO2 reacts

with the reservoir rocks to form carbonate minerals (mineralisation).

How does CCUS support carbon

removal?

CCUS technologies can provide

a means of removing CO2 from the atmosphere, i.e., “negative

emissions”, to offset emissions from sectors where reaching zero emissions may

not be economically or technically feasible. There are two principal

approaches:

Bioenergy with carbon capture

and storage, or BECCS, involves capturing and permanently storing CO2 from

processes where biomass (which extracts CO2 from the atmosphere

as it grows) is burned to generate energy. A power station fuelled with biomass

and equipped with CCUS is a type of BECCS technology, as are facilities that

process biomass into biofuels, if the resulting CO2 is captured

and stored.

Direct air capture (DAC)

involves the capture of CO2 directly from ambient air (as

opposed to a point source). The CO2 can be used, for example as

a climate-neutral CO2 feedstock in synthetic fuels, or it can

be permanently stored for carbon removal.

These technology-based

approaches for carbon removal can complement and supplement nature-based

solutions, such as afforestation and reforestation.

CCUS retrofits in the Sustainable Development Scenario

There are three options for

cutting locked-in emissions in the power generation and industrial sectors:

- Investing in modifications to existing

industrial and power equipment to either use less carbon-intensive fuels

or improve energy efficiency

- Retiring plants before the end of their

normal operating lifetimes, or making less use of them (e.g. by

repurposing fossil fuel power plants to operate at peak-load rather than

base-load)

- Retrofitting CO2 capture

facilities and storing or using the CO2.

Strategic value of CCUS

CCUS

carries considerable strategic value as a climate mitigation option. It can be

applied in a number of ways and across a range of sectors, offering the

potential to contribute – directly or indirectly – to emissions reductions in

almost all parts of the global energy system. Consequently, progress in

developing and deploying CCUS technologies in one sector could have significant

spill over benefits for other sectors or applications, including for

technological learning, cost reductions and infrastructure development. The

four main ways in which CCUS can contribute to the transition of the global

energy system to net-zero emissions – tackling emissions from existing energy

assets, providing a platform for low-carbon hydrogen production, a solution for

sectors with hard-to-abate emissions, and removing carbon from the atmosphere –

are listed below:

CCUS

can be retrofitted to existing power and industrial plants that could otherwise

emit 600 billion tonnes of CO2 over the next five decades –

almost 17 years’ worth of current annual emissions. In the Sustainable

Development Scenario an initial focus of CCUS is on retrofitting fossil

fuel-based power and industrial plants. By 2030, more than half of the CO2 captured

is from retrofitted existing assets.

2) A

cost-effective pathway for low-carbon hydrogen production

CCUS can support a rapid

scaling up of low-carbon hydrogen production to meet current and future demand

from new applications in transport, industry and buildings. CCUS is one of the

two main ways to produce low-carbon hydrogen.

Global hydrogen use in the

Sustainable Development Scenario increases sevenfold to 520 megatons (Mt) by

2070. The majority of the growth in low-carbon hydrogen production is from

water electrolysis using clean electricity, supported by 3 300 gigawatts (GW)

of electrolysers (from less than 0.2 GW today). The remaining 40% of low-carbon

hydrogen comes from fossil-based production that is equipped with CCUS,

particularly in regions with access to low-cost fossil fuels and CO2 storage.

CCUS is virtually the only

technology solution for deep emissions reductions from cement production. It is

also the most cost-effective approach in many regions to curb emissions in iron

and steel and chemicals manufacturing. Captured CO2 is a

critical part of the supply chain for synthetic fuels from CO2 and

hydrogen – one of a limited number of low-carbon options for long-distance

transport, particularly aviation.

4)

Removing carbon from the atmosphere

For emissions that cannot be

avoided or reduced directly, CCUS underpins an important technological approach

for removing carbon and delivering a net-zero energy system. When net-zero

emissions is reached in the Sustainable Development Scenario, 2.9 gigatons (Gt)

of emissions remain, notably in the transport and industry sectors. These

lingering emissions are offset by capturing CO2 from bioenergy

and the air and storing it.

Sources:

A new era for CCUS – CCUS in Clean Energy Transitions –

Analysis - IEA

CarbonCaptureUtilizationandStorage.pdf (need.org)

Storing CO2 underground can curb carbon emissions, but is it

safe? (phys.org)

Comments

Post a Comment